professional OEM Service Industrial High Magnesium Stainless Cast Iron Ss Brass Alloy Aluminum Pressure Die Casting

Product Descropition Table Company Profile Suzhou Jiali Mingyu import & Export Co., Ltd. is located in 111 Shishan Road,

Basic Info

| Model NO. | oem-cm-aluminum011 |

| After-sales Service | Other |

| Warranty | Other |

| Condition | New |

| Certification | CE, RoHS, GS, ISO9001 |

| Standard | DIN, ASTM, GOST, GB, JIS, ANSI |

| Customized | Customized |

| Material | Aluminum |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Surface Roughness | Ra1.6 |

| MOQ | 10 Piece |

| Delivery Time | 20-30 Days |

| Shipping Method | by Express, Air or Sea |

| Tolerance | +/-0.02mm |

| Finshed | According to Customer Request |

| Payment Term | Payment Term: 50% Deposit by T/T in Advance After |

| Transport Package | Cartons Packing, by Express, Air or Sea |

| Specification | Customized size |

| Trademark | JLMY |

| Origin | Su Zhou |

| Production Capacity | 1000000 Piece/Year |

Product Description

Product Descropition

Table

| Product Name | Turning Parts ,Brass Turning Parts ,CNC Turning Parts ,Casting Parts,Stamping Parts |

| Material | 1.Steel:303/304/316/412/etc |

| 2.Aluminum alloy:5052/6063/6020/6061/6080 | |

| 3.Brass alloy:3602/2604/H59/H62/etc | |

| 4.Steel Alloy :carbon steel/ die steel/etc | |

| 5.Other Special Materials :copper ,bronze,iron | |

| We handle many other type of materials . please contact us if your required materials are not listed material. | |

| Color | Customized |

| Surface Treatment | 1.White,blue ,silver zin plated |

| 2.Nickle/chrom/aluminum alloy plated | |

| 3.passivate | |

| 4.Powder Coating | |

| 5.Anodizing :black anodizing ,blue anodizing,clear anodizing,etc | |

| Polishing , Electroplate , baking finish, spray-painting, silk-screen, E-coating, Oxidation | |

| Processing | CNCmachine, Lathe machine,Milling machine ,drilling machine ,planning ,grinding ,boring ,tapping |

| Tolerance | +/-0.01~0.05mm,or as customer requirement |

| Delivery Time | Generally around two weekes ,but it will depends on the order quantity and product compexity Facilities |

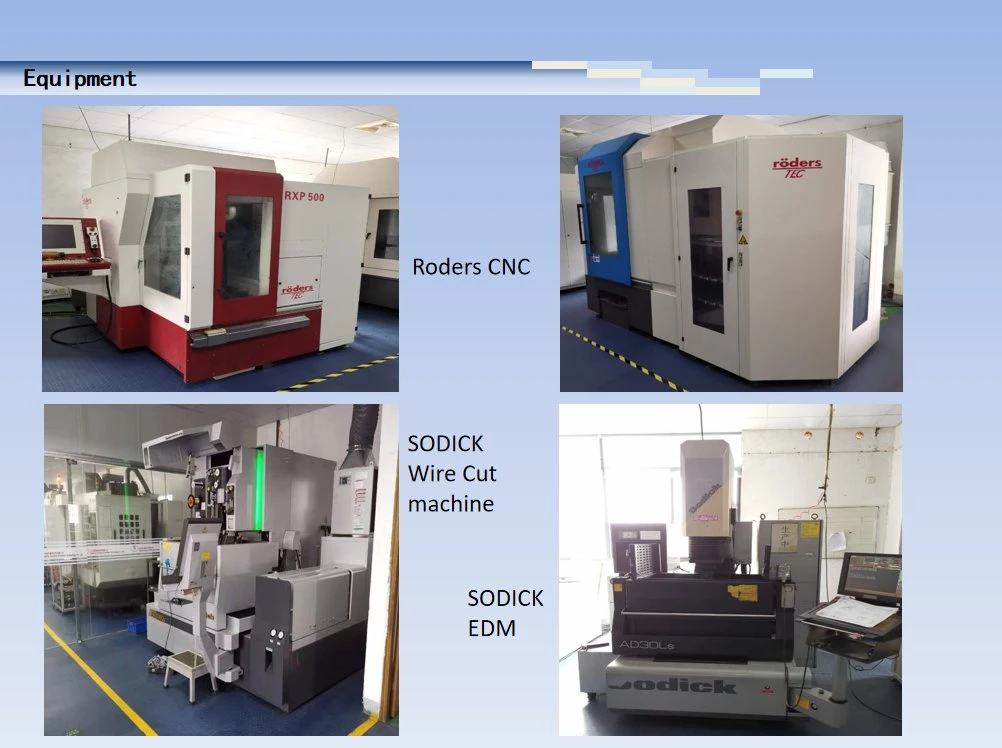

| Facilities | More than 25 CNC machines,6 sets precision turning machines,10 sets threading machines ,1 set auto-package line |

| Advantages | Professional precision manufacturer for more than 15 years. |

| 1. Quality control :We have experienced QC team that you can rely on.The defective products rate is 0.1%.Imported material is available if required. | |

| 2. We have reasonable price with precision made. | |

| 3. Each part would be given 100% test and tryout before shipment. | |

| 4. Adequate supply capacity. Punctual delivery time. | |

| 5. Best after sales service is provided. |

Company ProfileSuzhou Jiali Mingyu import & Export is located in 111 Shishan Road, Suzhou high-tech zone, and is a company integrating industry and trade. Our factory specializes in all kinds of hardware and plastic mold development, precision parts processing production, sales. We are a professional supplier of stamping parts, CNC machining parts, casting parts, Plastic injection parts, power tools and tool accessories. Products are widely used in auto parts, aerospace, medical equipment, precision equipment, power tools and other industries. Our factory 16 years of R & D, production and processing experience, Our factory is equipped with high precision Processing equipment imported from Germany and Japan. Our company's engineers have been working for many years and have accumulated rich experience in mold development and precision parts processing.Our factory has always been to strictly implement product quality control for the purpose, in strict accordance with customer requirements.Our company passed ISO9001:2008 international quality system certification in 2010 and TS16949 system certification in 2011. Our company has always been to provide quality fast service, high-quality products for the purpose, the pursuit of creating value for customers of the core values, to ensure that to provide customers with: higher quality, lower complaints, lower prices of products, 16 years of common growth with customers.

CNC machining center&Stamping and Casting workshopCNC machining center has 16-Body equipment, mainly producing automobile parts, precision equipment parts, aviation equipment, medical equipment and other design fields. The main processing materials are metal, copper, stainless steel, alloy, iron and other widely used fields. The production line is the latest professional equipment, monitoring and other first-class technology industries.

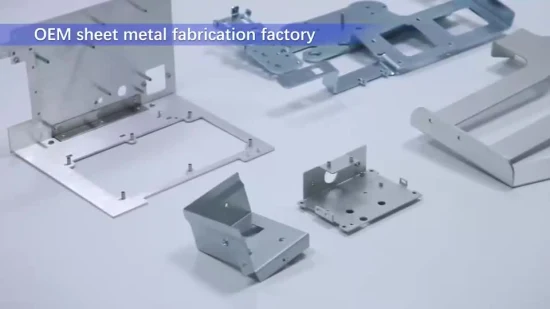

Products showWe can customize for you about the precision hardware and plastic products as below 1. All kinds of cnc machining; 2. Stamping & bending parts; 3. Plastic injection molding parts; 4. Casting & Forging parts.

Frequently Asked QuestionsFAQQ1. Are you a factory or trade company? We are an industry and trade integrated company, Our factory has a history of 16 years. Welcome to our factory. Q2. What kind of production service do you provide? All kinds of cnc machining;stamping & bending parts; casting & forging service.Plastic injection molding parts; Q3. How about the lead time? Mold 3-5 weeks;Mass production 3-4 weeks Q4. How long should we take for a quotation? After receiving detailed information we will quote within 2 days. Q5. What is your quotation element? Drawing or sample, Material, Finish and Quantity. Q6. What is your payment term? If the total amount <=3000USD, 100% payment in advance before the production.If the total amount >3000USD, 50% T/T deposit before production, 50% balance before shipmen

Send to us